Here is a video that explains the strength of ductile iron and why we chose ductile iron for our differential covers. It’s produced by a company called Spring City Electrical.

References below are from http://www.ductile.org/

The Ductile Iron Family

Ductile Iron is not a single material, but a family of materials offering a wide range of properties obtained through microstructure control. The common feature that all Ductile Irons share is the roughly spherical shape of the graphite nodules. These nodules act as “crack-arresters and make Ductile Iron “ductile”. This feature is essential to the quality and consistency of Ductile Iron, and is measured and controlled with a high degree of assurance by competent Ductile Iron foundries. With a high percentage of graphite nodules present in the structure, mechanical properties are determined by the Ductile Iron matrix. The relationship between microstructure and tensile strength over a wide range of properties.

A Matter of Confidence

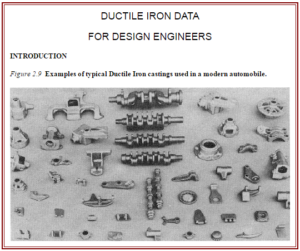

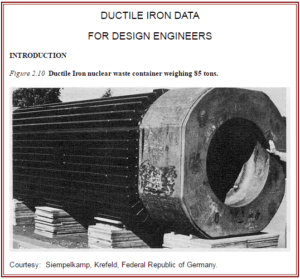

The automotive industry has expressed its confidence in Ductile Iron through the extensive use of this material in safety related components such as steering knuckles and brake calipers. These and other automotive applications, many of which are used “as-cast”, are shown in Figure 2.9. One of the most critical materials applications in the world is in containers for the storage and transportation of nuclear wastes. The Ductile Iron nuclear waste container shown in Figure 2.10 is another example of the ability of Ductile Iron to meet and surpass even the most critical qualification tests for materials performance. These figures show the wide variety of parts produced in Ductile Iron. The weight range of possible castings can be from less than one ounce (28 grams) to more than 200 tons. Section size can be as small as 2 mm to more than 20 inches (1/2 meter) in thickness.